Insert Molding & Overmolding

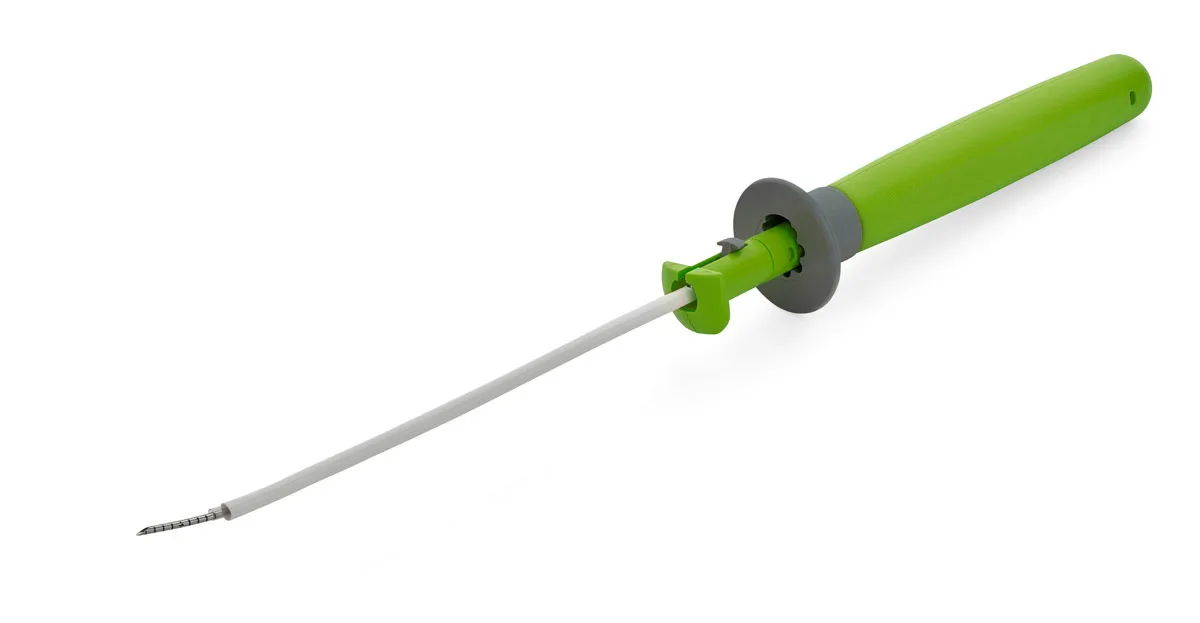

Insert Molding

Insert molding involves placing a plastic or metal component (the “insert”) into the mold before injecting plastic around it. This process encapsulates or integrates the insert into the final molded part. It creates a strong component without the need for secondary assembly steps.

Insert molding highlights

- Plastic is molded around a pre-formed non-plastic component, often metal

- Allows plastic and metal (or another material) to be combined into one part with plastic encapsulating the metal

- The molded plastic can protect the inner part and then allows for sterilization

- Creates a strong part without need of assembly

Examples of insert molding

- Handles molded onto the metal part of hand-held devices

- Hubs for drug delivery devices such as needles

- Hubs for oncology devices such as those used to collect biopsies

- Inhaler components

- Metering pump magnets

- Housings for pacemakers

- Housings for endoscopy devices

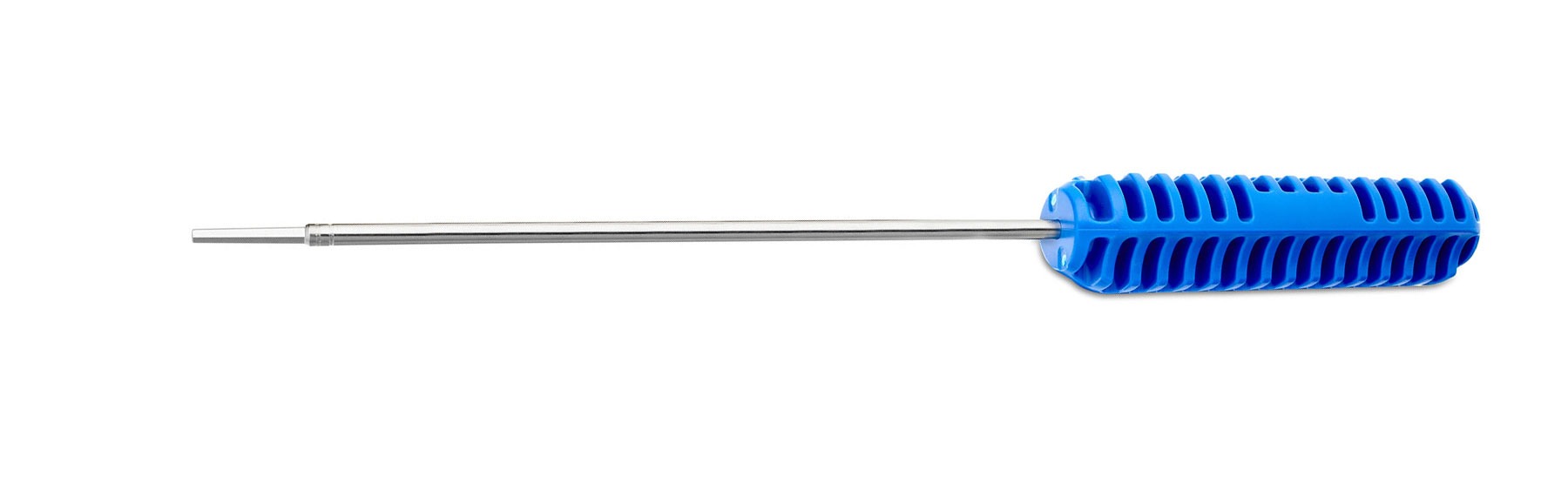

Overmolding

Overmolding allows us to apply multiple layers of materials onto a base component, enhancing device functionality, grip, and ergonomics. By over-molding plastics over metals or other plastics, we create custom, multi-material parts that offer comfort, durability, and improved functionality.

Overmolding highlights

- Enhanced ergonomics and usability of medical devices

- Creates strong bond between materials

- Supports a wide range of material combinations

- Enables intricate designs

Examples of Use

- Ergonomic handles for precision medical devices

- Housings for diagnostic equipment like glucose monitors or ultrasound devices

- Insulin pens and auto-injectors with textured grips for ease of handling

- Pacemaker or defibrillator components with protective over-molded coatings

- Handles and grips for joint replacement and spinal surgery tools

- Wearable medical devices

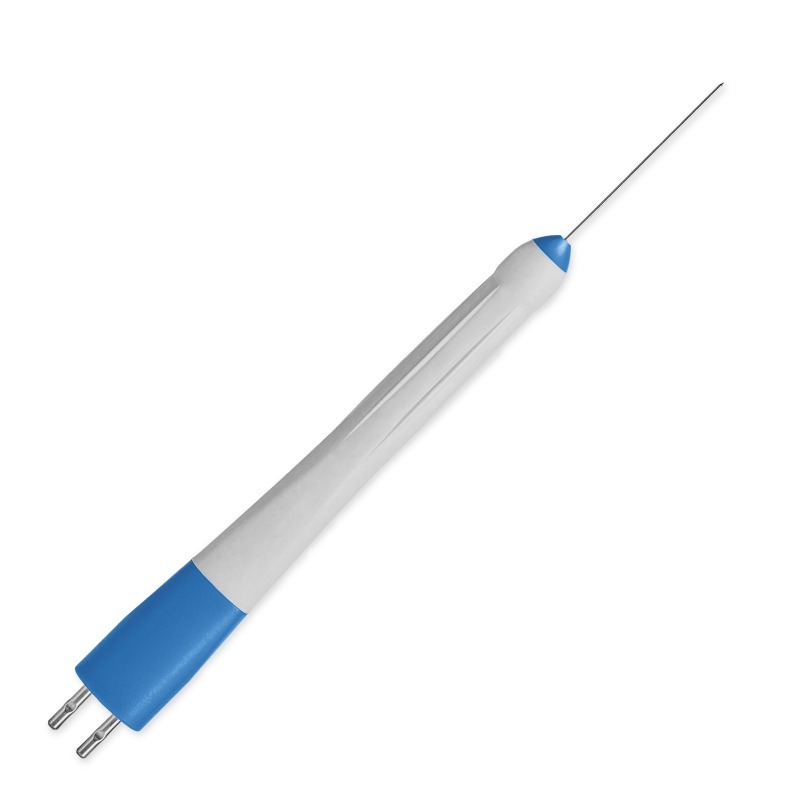

Two-Shot Molding

Two-shot molding and insert molding are often confused, but each technology offers different benefits and applications for medical devices.

Two-shot molding, also known as 2K molding or double-shot molding combines two different thermoplastics into a single molded component. Two shot molding creates complex, multi-color, multi-material devices and components.

Two-shot molding highlights

- Combines two different thermoplastics into a single molded component

- Creates complex, multi-color, multi-material components

- Consolidates the number of parts

- Bonds are stronger than those from joining separate parts after molding

- Tighter tolerances

- Improved repeatability and accuracy

- Uses rotary table technology, index plate systems, and core-back technology as needed

- Expert, in-house mold building and decades of experience

Examples of two-shot molding

- Instrument handles with a hard core and softer, ergonomic outer material

- Hearing aids

- Pacemakers and implantable cardioverter-defibrillators (ICD)

- Cardiovascular home monitoring devices

- Drug delivery devices

- Abutments for dental implants

Let’s Start the Conversation

Your next project begins with a conversation. Reach out to us today and let’s discuss your needs.